WaterJet Services

Waterjet services utilize high-pressure water jets to cut or engrave a variety of materials with precision and versatility. Our offerings include cutting on stone, tiles, marble, stainless steel, rubber, and more, making it an ideal solution for intricate designs and complex shapes. The process is known for its ability to produce clean edges without harmful heat, ensuring that even delicate materials are handled with care while achieving outstanding results. We use Flow Waterjet machines to give the best results.

Tiles Cutting

Waterjet tile cutting is a precision technique that can cut various types of tiles of all sizes. The process is efficient and environmentally friendly, as it produces minimal waste and can be done quickly compared to traditional cutting methods. Waterjet cutting is ideal for both large-scale projects and custom designs, providing a clean edge and superior finish.

Stone Cutting

Waterjet technology can effortlessly cut through stones up to 100 mm thick, making it an ideal choice for both architectural applications and artistic designs. Its versatility and capability to handle complex shapes set waterjet cutting apart as a preferred option in the stone fabrication industry.

Metal Cutting

Waterjet is particularly effective for cutting stainless steel (SS), mild steel (MS), and other alloys, resulting in clean edges without affecting the material properties. The versatility of waterjet technology allows for intricate designs and shapes, making it a preferred choice in industries requiring high accuracy and minimal thermal distortion.

Stone and marble services

We offer a wide range of stone and marble services, including intricate moulding that enhances architectural features, exquisite inlay designs that add elegance through detailed craftsmanship, and advanced 3D carving for creating stunning visual effects in various applications. Our expertise ensures high-quality finishes tailored to meet unique client needs.

Marble Inlay

Marble inlay using mother of pearl (MOP) is a stunning decorative technique where intricate designs are created by setting pieces of MOP into the surface of marble. The iridescent quality of mother of pearl adds a captivating shine and depth, contrasting beautifully with the cool, smooth texture of marble. This craft often involves meticulous cutting and shaping of the MOP to fit perfectly within the marble’s design, enhancing the elegance of tabletops, floors, or wall art. The result is a luxurious visual harmony that elevates any space with its artistic expression and craftsmanship.

3D stone carving

CNC (Computer Numerical Control) machines have revolutionized the art of 3D stone carving by allowing for precise and intricate designs to be crafted on a variety of stone and marble thicknesses. These machines utilize advanced software to translate digital designs into physical carvings, enabling artists and manufacturers to create complex shapes and detailed textures that would be difficult to achieve by hand. The process begins with selecting the type of stone or marble, which can vary significantly in density and hardness; this choice impacts the machining strategy. Once the material is secured, the CNC machine uses diamond-tipped tools to gradually carve away layers of stone, providing a level of detail and repeatability unmatched in traditional methods. Additionally, the ability to adjust the tool paths allows for customization across different thicknesses of stone, ensuring that each piece, regardless of its dimensions, maintains high quality and precision in the final output.

Marble mouldings

Making marble mouldings using CNC profiling machines involves several precise steps. First, a digital design of the moulding is created using CAD software, ensuring accurate dimensions and details. The CNC machine begins the process by securing a marble block and using a diamond-tipped cutting tool to carve the moulding profile according to the design specifications. Throughout the milling process, water is used for cooling and to reduce dust, maintaining the quality of the marble surface. Once the initial shape is formed, finishing tools may be employed to smooth edges and achieve the desired surface finish. Finally, the moulding can be polished to enhance its natural luster, ready for installation.

Corian solid surface work

Corian solid surface is a versatile and durable material commonly used for countertops, basins, wall claddings, and even decorative features like Backlit Mandirs. Renowned for its seamless appearance, Corian can be easily molded to create elegant designs without visible joints, making it highly popular in contemporary kitchens and bathrooms. Its non-porous nature ensures a hygienic surface that resists stains and bacteria, while also allowing for easy cleaning and maintenance. Available in a wide range of colors and patterns, Corian offers aesthetic flexibility, enabling homeowners to customize their spaces seamlessly. Additionally, its ability to be thermoformed allows for unique shapes and designs, making it an ideal choice for both functional surfaces and intricate architectural elements like mandirs.

CNC carving 2D and 3D

The smooth, versatile nature of Corian allows for detailed carvings and engravings, enabling artisans to manifest divine imagery and mantras that enhance spiritual spaces. Through this innovative process, complex patterns and reliefs like Divine mantras and 3D God pictures are brought to life, embodying both aesthetic beauty and sacred significance, resulting in stunning pieces that resonate with meditative energy and devotion.

Basins/Vanity and counter tops

Solid surface acrylic is widely used in the creation of basins, vanities, and countertops due to its versatility, durability, and aesthetic appeal. This non-porous material is resistant to stains, bacteria, and moisture, making it an ideal choice for areas that require hygienic surfaces, such as bathrooms and kitchens. Its seamless construction allows for easy integration into various designs, providing clean lines and a modern look. The material can be easily fabricated, shaped, and customized in a variety of colors and finishes, giving designers and homeowners the flexibility to achieve their desired aesthetic. Additionally, solid surface acrylic can be repaired easily in case of scratches or damages, further enhancing its longevity and practicality in high-traffic spaces.

Customised mandirs

Creating customized mandirs involves a detailed process where artisans collaborate closely with clients to understand their specific requirements. Initially, consultations help gather insights on dimensions, designs, and materials. Based on these discussions, sketches or digital models are crafted to visualize the mandir, ensuring it aligns with the customer’s vision. Once the design is approved, high-quality materials like wood or stone are sourced, and skilled craftsmen begin the intricate work of carving and assembling the mandir. Attention is paid to traditional motifs and personal touches, catering to the unique preferences of each client. After completion, the mandir undergoes a thorough quality check before delivery, ensuring it meets the highest standards and fulfills the spiritual needs of the customer.

CNC cutting

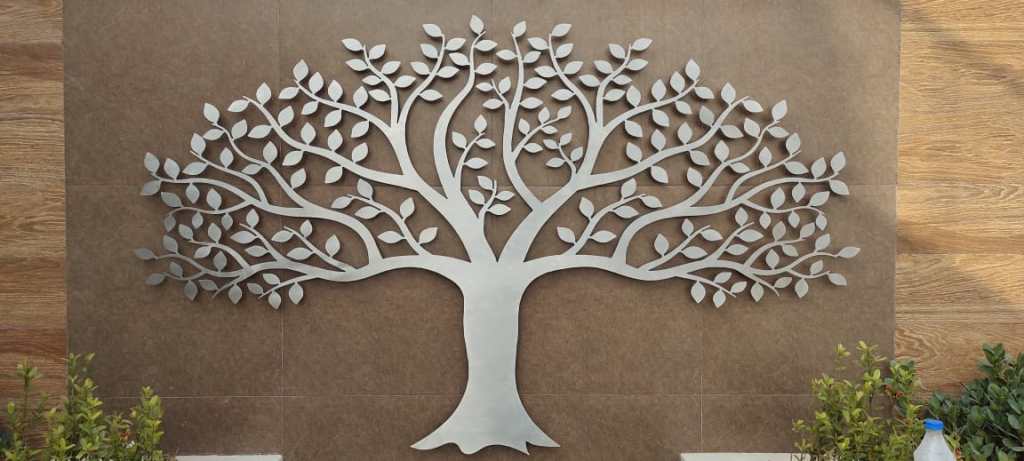

CNC Metal cutting

CNC laser metal cutting is a precise manufacturing process that utilizes a high-powered laser to cut through various types of metals, making it ideal for creating intricate wall art, decorative gates, and personalized signage. The process begins with a computer-aided design (CAD) model, where artists and designers can specify complex patterns and details. Once the design is uploaded to the CNC machine, the laser beam is directed onto the metal surface, melting or vaporizing the material with incredible accuracy, resulting in clean edges and finely detailed cuts. This technology allows for customization and scalability, making it possible to produce unique, high-quality pieces that can enhance any space or serve functional purposes, while also offering durability and resistance to the elements.

Sandblasting

Sandblasting on tiles and marble is a technique that involves using high-pressure air to propel fine sand or abrasive materials at the surface of the stone, creating intricate designs and textures. This process allows artisans to achieve detailed patterns, logos, or images on the hard surfaces, enhancing their aesthetic appeal. The depth and clarity of the designs depend on the pressure used and the size of the abrasive particles, enabling varied finishes from subtle etches to deep carvings. Sandblasting is not only effective for decorative purposes but also offers functional benefits, such as improving grip on polished surfaces.

CNC Router

3D wood carving using a CNC router is an innovative technique that allows artisans to create intricate and elegant designs for walls and ceilings. This process begins with a digital design, crafted using specialized software, which dictates the precise dimensions and details of the carving. The CNC router, equipped with sharp cutting tools, follows these digital blueprints with remarkable accuracy, skillfully removing material from wooden boards to reveal stunning three-dimensional patterns and textures. The result is a luxurious finish that adds depth and character to interior spaces, transforming ordinary walls and ceilings into captivating focal points that reflect craftsmanship and artistry. Furthermore, these carvings can incorporate diverse styles, from classic motifs to contemporary designs, allowing for endless customization that caters to individual tastes and interior aesthetics.